Precision Aluminum Spinning for LED Lighting

Seamless • Uniform • High-Precision

🔷Introduction

Aluminum metal spinning is a precision forming process widely used for LED lighting components.

It provides high dimensional accuracy, excellent consistency, and a smooth surface finish suitable for both functional and decorative lighting applications.

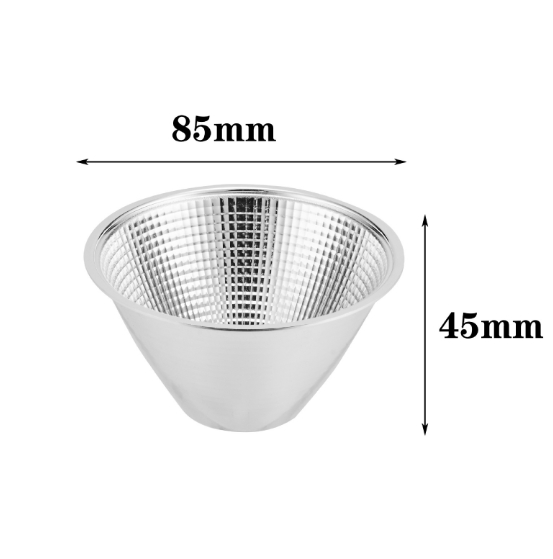

Ideal for producing LED reflectors, housings, lamp shades, and heat-dissipating components, metal spinning ensures strength, lightweight performance, and cost efficiency.

🔷Features

- High Precision Forming Consistent dimensions and shape accuracy for LED reflectors and housings.

- Superior Surface Finish Smooth and clean surfaces suitable for anodizing, powder coating, brushing, and polishing.

- Excellent Heat Dissipation Aluminum material enhances thermal performance for LED systems.

- Lightweight & Durable Strong structural integrity with minimal weight.

- Flexible Customization Supports various diameters, depths, thicknesses, and profiles.

- Cost-Effective for Small to Medium Batches Lower tooling cost compared to die-casting or deep drawing.

- Material Options 1050, 1060, 1100, 3003, 5052, 6061 and other aluminum alloys.

🔷Specifications

1. Material

- Aluminum alloys: 1050 / 1060 / 1100 / 3003 / 5052 / 6061

- Thickness: 0.5 mm – 5.0 mm

2. Dimensions & Tolerances

- Diameter range: custom sizes available

- Depth range: according to customer design

- Tolerance: ±0.1–0.3 mm depending on size and complexity

3. Surface Finish Options

- Anodizing (clear, black, champagne, bronze, etc.)

- Powder coating

- Sandblasting / brushing

- Polishing

- Painting

4. Production Capacity

- Prototype orders to mass production

- Spinning + trimming + punching + CNC machining available

5. Quality Assurance

- Strict dimensional inspection

- Material certification available

- Surface finish inspection

- Sample approval before mass production

🔷Applications

- LED downlight reflectors

- LED high-bay light housings

- Outdoor and industrial LED lamp covers

- Decorative lamp shades

- Streetlight reflectors

- Architectural and commercial lighting components

🔷Why Choose Us?

- Over 16 years of metal spinning experience

- Advanced CNC spinning machines

- Fast lead times and competitive prices

- Engineering support for design optimization

- Reliable packaging and global shipping

🔷Customization Services

- Customer provides drawing or sample

- Engineering evaluation & quotation

- Tooling preparation (if required)

- Sample production and confirmation

- Mass production

- Quality inspection & shipping

🔷Contact Us

- For inquiries, custom designs, or quotations, please send it to sophia@glarysh.com .