Anodizing, Plating & Coating — Protection Meets Precision

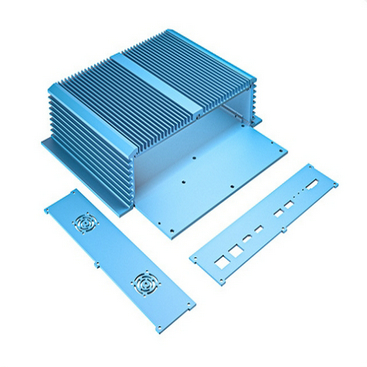

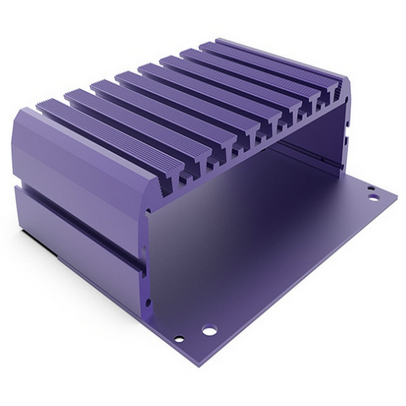

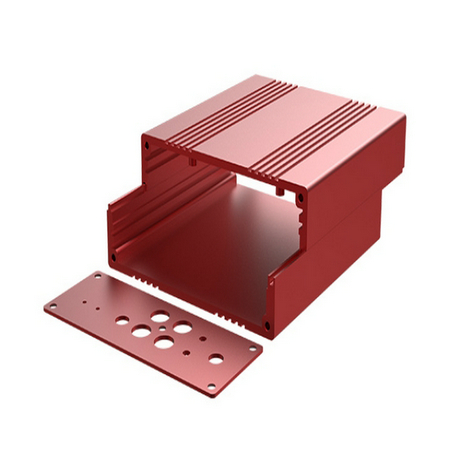

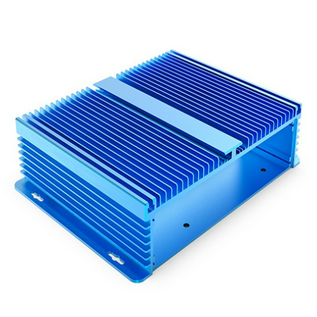

Improve corrosion resistance, thermal performance, and aesthetics with tailored finishes for your aluminum heatsinks.

🔷Product Overview

Our die casting aluminum heatsinks are engineered for superior heat dissipation and durability. Designed for demanding applications in electronics, LED lighting, automotive, and renewable energy systems.

🔷Features

- Corrosion protection — Extend service life in harsh environments.

- Improved thermal emissivity — Better heat dissipation via anodizing or coatings.

- Enhanced appearance — Color matching and branding options.

🔷Common Surface Treatment Options

- 1. Anodizing

- Hard anodizing for wear resistance

- Decorative anodizing with color choices (black, silver, red, blue, gold, etc.)

- Improves emissivity and corrosion resistance

- 2. Powder Coating

- Durable, colorful finish

- Good for non-critical thermal surfaces

- Excellent mechanical protection

- 3. Chromate Conversion Coating (Alodine)

- Conductive surface for EMI shielding

- Corrosion protection without changing dimensions

- Suitable for grounding applications

- 4. Electroplating

- Nickel, tin, or silver plating for conductivity

- Enhanced wear resistance and corrosion protection

- 5. Sandblasting / Polishing /Matte

- Uniform surface texture before anodizing or painting

- Improves adhesion of coatings

- 6. Laser Engraving

- Permanent, high-contrast marking for part numbers, logos, or serial codes

- No ink, no fading — resistant to wear, heat, and chemicals

- Can be applied directly to anodized or bare aluminum

- Ideal for branding, traceability, and compliance markings

🔷Surface Treatment Comparison Table

| Process | Typical Thickness | Corrosion Resistance | Wear Resistance | Thermal Effect | Appearance & Color Options | Special Advantages |

| Anodizing | 5–30 µm | ★★★★☆ | ★★★☆☆ | ↑ Improves emissivity | Black, silver, red, blue, gold, custom colors | Increases heat radiation, strong corrosion protection |

| Powder Coating | 50–150 µm | ★★★★☆ | ★★★★☆ | ↓ Slightly lower | Wide RAL/Pantone range | Excellent mechanical durability, thick protective layer |

| Chromate Conversion | <1 µm | ★★★☆☆ | ★★☆☆☆ | Neutral | Yellow, clear, olive drab | Maintains conductivity, good for EMI shielding |

| Electroplating | 5–10 µm | ★★★★☆ | ★★★★☆ | ↓ Slightly lower | Metallic finish (nickel, tin, silver) | High conductivity, good wear protection |

| Sandblasting / Polishing/ Matte | N/A | Depends on top coat | ★★☆☆☆ | Neutral | Matte or brushed metallic | Creates uniform texture, improves coating adhesion |

| Laser Engraving | N/A | N/A | Permanent mark | Neutral | High-contrast engraving (usually white on anodized) | Permanent, precise branding & traceability without chemicals |

🔷Applications

- Outdoor LED lighting

- Marine and automotive electronics

- Aerospace electronics modules

- Telecom base stations

- Industrial power inverters

🔷Custom Order & Contact

- Custom Manufacturing to Your Specifications

Our engineering team works closely with you. We ensure precise dimensions and optimal thermal performance. We also focus on cost-effective production. - Send us your requirements today, and we’ll provide a tailored solution and competitive quotation.