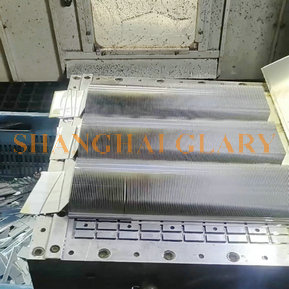

Skiving Aluminum Heatsink

High‑Efficiency, Precision‑Formed Thermal Solutions

Ultra‑thin fins, superior thermal performance and low cost-per-Watt — custom profiles manufactured with precision skiving for LED, power electronics, etc.

🔷Product Overview

Skiving is a mechanical machining technique.

It produces continuous, high-aspect-ratio fins by shaving the aluminum parent material.

This process delivers superior thermal conductivity.

It provides minimal thermal resistance and excellent mechanical integrity compared with bonded fin methods.

🔷Features

Thermal Efficiency: Continuous metal path reduces thermal resistance.Scalability: From prototype to volume production.Design Freedom: Unusual cross-sections and footprint options.Durability: Mechanically robust, vibration resistant.

🔷Technical Specifications

Material: 6061-T6 or 6063-T5 aluminum

Fin thickness (typical): 0.1–0.6 mm

Fin pitch: 0.5–6.0 mm

Base thickness: 1.0–10.0 mm (custom)

Max fin height: up to 80 mm (application dependent)

Thermal interface options: TIM grooves, solderable surfaces

Surface finish: Anodize (clear/black), nickel plating, powder coat

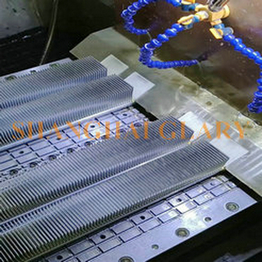

🔷Manufacturing Process

Design & Engineering — Thermal simulations & custom profile CAD.Skiving / Forming — Precision skiving (fin pitch from X mm to Y mm, depths to Z mm).CNC Machining — Holes, slots, mounting features.Finishing — Anodize, bead blast, plating as required.Inspection & Test — Dimensional QC, thermal testing.Packing & Shipping — ESD-safe, customized packaging.

🔷Applications

LED lighting & luminaries

Power electronics & converters

Telecom base stations & networking equipment

Automotive electronics & inverters

🔷Custom Order & Contact

Custom Manufacturing to Your Specifications Send us your requirements today , and we’ll provide a tailored solution and competitive quotation.