Stamping Aluminum Heatsink

High-Volume Stamped Aluminum Heatsinks — Fast. Cost-Effective. Reliable.

Cost-effective thermal solutions for high-volume applications — precise stamped fins, consistent performance, and flexible finish options.

🔷Product Overview

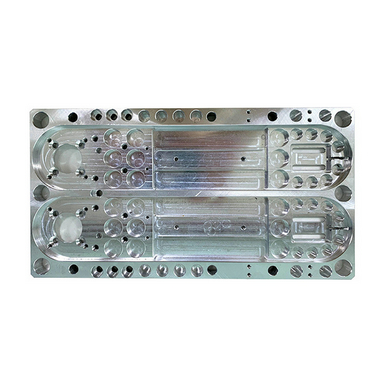

Stamped heatsinks are formed from sheet aluminum using progressive dies and presses that cut, bend and form fin arrays.

They deliver a balance of thermal performance and cost advantages for LED lighting, power supplies, consumer electronics and appliance markets.

🔷Features

Low unit cost at scale — optimized for medium-to-high production volumes.Repeatable geometry — high dimensional consistency across long runs.Design flexibility — various fin shapes, louvers and integrated mounting tabs.

🔷Technical Specifications

Material: 1050 aluminum (custom alloys available)Sheet thickness: 0.3–2.0 mm (typical)Fin height: 2–40 mm (depends on design)Fin pitch: 0.5–6.0 mm (design dependent)Max strip width: up to 350 mm (replace per capability)Finish options: anodize, powder coat, platingProduction rate: presses from 30–300 SPM (strokes per minute)

🔷Manufacturing Process

Design for manufacturability (DFM) & tool design

Progressive die manufacturing

High-speed stamping & forming

Secondary operations (bending, tapping, spot welding)

Surface treatment (anodize, coating, plating)

Quality inspection & packing

🔷Applications

LED lighting

Power supply & converter cooling

Consumer electronics (set-top boxes, chargers)

Household appliances (motors, inverters)

🔷Custom Order & Contact

Custom Manufacturing to Your Specifications Send us your requirements today , and we’ll provide a tailored solution and competitive quotation.